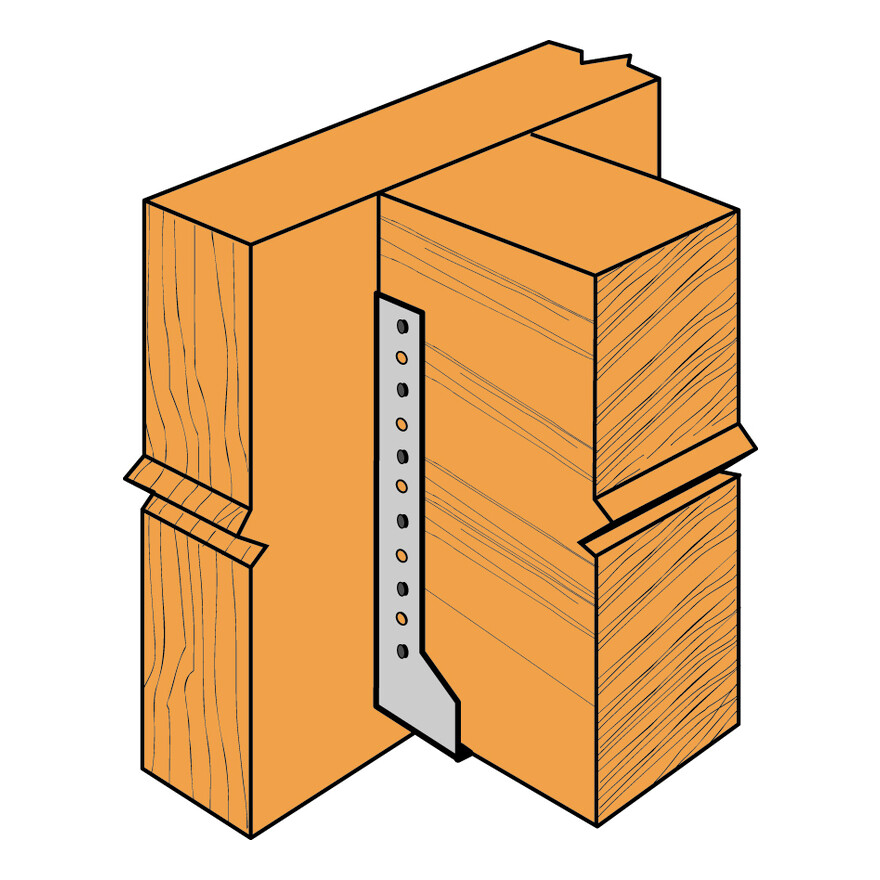

Balkenschuhe mit innenliegenden Flanschen

Balkenschuhe GSI eignen sich vornehmlich zur Befestigung größerer Brettschichthölzer an Holz. Sie dienen speziell den Anschlüssen mit höheren BSH Querschnitten.

In der Materialstärke 4,0 mm in Verbindung mit CNA 4,0x75 Kammnägeln ist eine Brandschutzausführung für R30 zugelassen.

Produkt-Details

Eigenschaften

Material

Stahlqualität:

- S 250 GD +Z 275 gemäß DIN EN 10346

Korrosionsschutz:

- 275 g/m2 beidseitig - entsprechend einer Zinkschichtdicke von ca. 20 μm

Blechdicke: 4,0 mm

Vorteile

- Schnelle und einfache Installation

- In der Materialstärke 4,0 mm in Verbindung mit CNA 4,0x75 Kammnägeln ist eine Brandschutzausführung für R30 zugelassen. Heißbemessung siehe ETA.

Anwendung

Anwendbare Materialien

Hauptträger:

Holz, Holzwerkstoffe

Nebenträger:

Holz, Holzwerkstoffe

- Befestigung an Beton, Mauerwerk und Stahl ist nicht zulässig.

Technische Daten

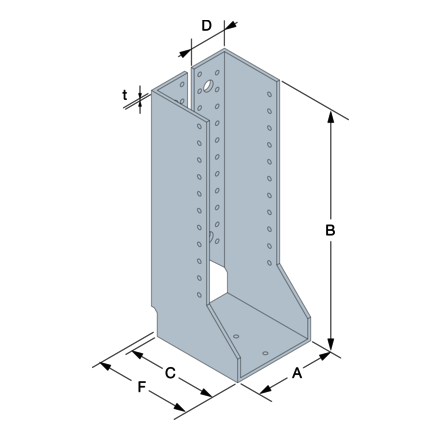

Abmessungen

| Artikel | Abmessungen [mm] | Löcher im Hauptträger | Löcher im Nebenträger | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | F | t | Ø5 | Ø13 | Ø5 | |

| GSI380/100/4 | 100 | 140 | 110 | 45.5 | 118 | 4 | 16 | 4 | 8 |

| GSI440/100/4 | 100 | 170 | 110 | 45.5 | 118 | 4 | 22 | 4 | 12 |

| GSI500/100/4 | 100 | 200 | 110 | 45.5 | 118 | 4 | 28 | 4 | 14 |

| GSI540/100/4 | 100 | 220 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/100/4 | 100 | 250 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/100/4 | 100 | 280 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/100/4 | 100 | 310 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/100/4 | 100 | 340 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/100/4 | 100 | 370 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/100/4 | 100 | 400 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/100/4 | 100 | 430 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/100/4 | 100 | 460 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

| GSI540/120/4 | 120 | 210 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/120/4 | 120 | 240 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/120/4 | 120 | 270 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/120/4 | 120 | 300 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/120/4 | 120 | 330 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/120/4 | 120 | 360 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/120/4 | 120 | 390 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/120/4 | 120 | 420 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/120/4 | 120 | 450 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

| GSI500/140/4 | 140 | 180 | 110 | 45.5 | 118 | 4 | 28 | 2 | 14 |

| GSI540/140/4 | 140 | 200 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/140/4 | 140 | 230 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/140/4 | 140 | 260 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/140/4 | 140 | 290 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/140/4 | 140 | 320 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/140/4 | 140 | 350 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/140/4 | 140 | 380 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/140/4 | 140 | 410 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/140/4 | 140 | 440 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

| GSI500/160/4 | 160 | 170 | 110 | 45.5 | 118 | 4 | 28 | 2 | 14 |

| GSI540/160/4 | 160 | 190 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/160/4 | 160 | 220 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/160/4 | 160 | 250 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/160/4 | 160 | 280 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/160/4 | 160 | 310 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/160/4 | 160 | 340 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/160/4 | 160 | 370 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/160/4 | 160 | 400 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/160/4 | 160 | 430 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

| GSI500/180/4 | 180 | 160 | 110 | 45.5 | 118 | 4 | 28 | 2 | 14 |

| GSI540/180/4 | 180 | 180 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/180/4 | 180 | 210 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/180/4 | 180 | 240 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/180/4 | 180 | 270 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/180/4 | 180 | 300 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/180/4 | 180 | 330 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/180/4 | 180 | 360 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/180/4 | 180 | 390 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/180/4 | 180 | 420 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

| GSI500/200/4 | 200 | 150 | 110 | 45.5 | 118 | 4 | 28 | 2 | 14 |

| GSI540/200/4 | 200 | 170 | 110 | 45.5 | 118 | 4 | 32 | 4 | 16 |

| GSI600/200/4 | 200 | 200 | 110 | 45.5 | 118 | 4 | 38 | 4 | 20 |

| GSI660/200/4 | 200 | 230 | 110 | 45.5 | 118 | 4 | 44 | 6 | 22 |

| GSI720/200/4 | 200 | 260 | 110 | 45.5 | 118 | 4 | 50 | 6 | 26 |

| GSI780/200/4 | 200 | 290 | 110 | 45.5 | 118 | 4 | 56 | 6 | 28 |

| GSI840/200/4 | 200 | 320 | 110 | 45.5 | 118 | 4 | 62 | 6 | 32 |

| GSI900/200/4 | 200 | 350 | 110 | 45.5 | 118 | 4 | 68 | 6 | 38 |

| GSI960/200/4 | 200 | 380 | 110 | 45.5 | 118 | 4 | 74 | 6 | 38 |

| GSI1020/200/4 | 200 | 410 | 110 | 45.5 | 118 | 4 | 80 | 6 | 40 |

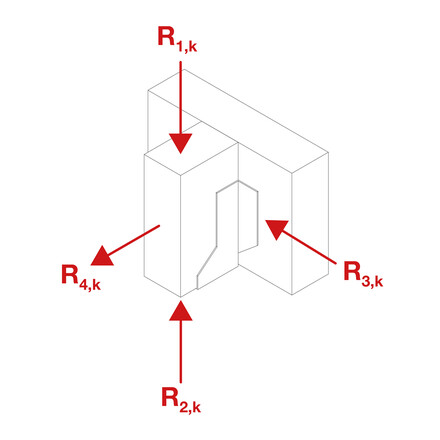

Charakteristische Tragfähigkeiten - Holz an Holz - Vollausnagelung

| Artikel | Charakter. Tragfähigkeit - Holz an Holz - Vollausnagelung | ||||||

|---|---|---|---|---|---|---|---|

| Verbindungsmittel | Charakter. Tragfähigkeiten - Nadelholz C24 [kN] | ||||||

| Hauptträger | Nebenträger | R1.k | R2.k | R3.k | R4.k | Brandschutz R1,k | |

| Anzahl | Anzahl | CNA4,0x50 | CNA4,0x50 | CNA4,0x50 | CNA4,0x50 | CNA4.0x75 | |

| GSI380/100/4 | 16 | 8 | 15.4 | 6.9 | 6.6 | 7.8 | 1,0* |

| GSI440/100/4 | 22 | 12 | 22.3 | 11.9 | 9.6 | 11.8 | 2,5* |

| GSI500/100/4 | 28 | 14 | 30.5 | 18.1 | 10.7 | 13.7 | 3,5* |

| GSI540/100/4 | 32 | 16 | 35.9 | 22.7 | 11.8 | 15.7 | 4,7* |

| GSI600/100/4 | 38 | 20 | 43.9 | 30.5 | 14 | 19.6 | 7,3* |

| GSI660/100/4 | 44 | 22 | 47.9 | 39 | 14.6 | 21.6 | 8,6* |

| GSI720/100/4 | 50 | 26 | 55.8 | 46.1 | 16.3 | 25.5 | 11,4* |

| GSI780/100/4 | 56 | 28 | 59.8 | 49.6 | 16.6 | 27.4 | 12,8* |

| GSI840/100/4 | 62 | 32 | 67.8 | 56.7 | 17.9 | 31.4 | 15,4* |

| GSI900/100/4 | 68 | 36 | 75.8 | 63.8 | 19 | 33.3 | 18,0* |

| GSI960/100/4 | 74 | 38 | 79.8 | 67.4 | 19 | 37.2 | 19,3* |

| GSI1020/100/4 | 80 | 40 | 83.8 | 70.9 | 18.9 | 39.2 | 20,6* |

| GSI540/120/4 | 32 | 16 | 34 | 22.7 | 12.7 | 15.7 | 4,7* |

| GSI600/120/4 | 38 | 20 | 43.1 | 30.5 | 15.2 | 19.6 | 7,3* |

| GSI660/120/4 | 44 | 22 | 47.9 | 39 | 16 | 21.6 | 8,6* |

| GSI720/120/4 | 50 | 26 | 55.8 | 46.1 | 18 | 25.5 | 11,4* |

| GSI780/120/4 | 56 | 28 | 59.8 | 49.6 | 18.5 | 27.4 | 12,8* |

| GSI840/120/4 | 62 | 32 | 67.8 | 56.7 | 20.1 | 31.4 | 15,4* |

| GSI900/120/4 | 68 | 36 | 75.8 | 63.8 | 21.5 | 33.3 | 18,0* |

| GSI960/120/4 | 74 | 38 | 79.8 | 67.4 | 21.6 | 37.2 | 19,3* |

| GSI1020/120/4 | 80 | 40 | 83.8 | 70.9 | 21.6 | 39.2 | 20,6* |

| GSI500/140/4 | 22 | 12 | 24.1 | 11.9 | 10.5 | 11.8 | 2,5* |

| GSI540/140/4 | 26 | 14 | 29.5 | 15.9 | 12 | 11.8 | 3,5* |

| GSI600/140/4 | 32 | 18 | 38.2 | 22.7 | 15 | 15.7 | 5,9* |

| GSI660/140/4 | 38 | 20 | 43.9 | 30.5 | 16.1 | 19.6 | 7,3* |

| GSI720/140/4 | 44 | 24 | 51.9 | 39 | 18.6 | 23.5 | 10,0* |

| GSI780/140/4 | 50 | 26 | 55.8 | 46.1 | 19.3 | 25.5 | 11,4* |

| GSI840/140/4 | 56 | 30 | 63.8 | 53.2 | 21.4 | 29.4 | 14,1* |

| GSI900/140/4 | 62 | 32 | 67.8 | 56.7 | 21.8 | 31.4 | 15,4* |

| GSI960/140/4 | 68 | 34 | 71.8 | 60.3 | 22.2 | 33.3 | 16,8* |

| GSI1020/140/4 | 74 | 38 | 79.8 | 67.4 | 23.8 | 37.2 | 19,3* |

| GSI500/160/4 | 22 | 12 | 22.3 | 11.9 | 10.7 | 11.8 | 2,5* |

| GSI540/160/4 | 26 | 14 | 27.6 | 15.9 | 12.3 | 11.8 | 3,5* |

| GSI600/160/4 | 32 | 18 | 36.1 | 22.7 | 15.5 | 15.7 | 5,9* |

| GSI660/160/4 | 44 | 24 | 51.9 | 39 | 20.1 | 19.6 | 7,3* |

| GSI720/160/4 | 44 | 24 | 51.9 | 39 | 19.5 | 23.5 | 10,0* |

| GSI780/160/4 | 50 | 26 | 55.8 | 46.1 | 20.4 | 25.5 | 11,4* |

| GSI840/160/4 | 56 | 30 | 63.8 | 53.2 | 22.7 | 29.4 | 14,1* |

| GSI900/160/4 | 62 | 32 | 67.8 | 56.7 | 23.3 | 31.4 | 15,4* |

| GSI960/160/4 | 68 | 34 | 71.8 | 60.3 | 23.8 | 33.3 | 16,8* |

| GSI1020/160/4 | 74 | 38 | 79.8 | 67.4 | 25.6 | 37.2 | 19,3* |

| GSI500/180/4 | 22 | 12 | 20.3 | 11.9 | 10.9 | 11.8 | 2,5* |

| GSI540/180/4 | 26 | 14 | 25.4 | 15.9 | 12.6 | 11.8 | 3,5* |

| GSI600/180/4 | 32 | 18 | 33.8 | 22.7 | 15.9 | 15.7 | 5,9* |

| GSI660/180/4 | 44 | 24 | 51.9 | 39 | 20.7 | 19.6 | 7,3* |

| GSI720/180/4 | 44 | 24 | 51.9 | 39 | 20.1 | 23.5 | 10,0* |

| GSI780/180/4 | 50 | 26 | 55.8 | 46.1 | 21.2 | 25.5 | 11,4* |

| GSI840/180/4 | 56 | 30 | 63.8 | 53.2 | 23.7 | 29.4 | 14,1* |

| GSI900/180/4 | 62 | 32 | 67.8 | 56.7 | 24.5 | 31.4 | 15,4* |

| GSI960/180/4 | 68 | 34 | 71.8 | 60.3 | 25.1 | 33.3 | 16,8* |

| GSI1020/180/4 | 74 | 38 | 79.8 | 67.4 | 27.2 | 37.2 | 19,3* |

| GSI500/200/4 | 22 | 12 | 18.3 | 11.9 | 11.1 | 11.8 | 2,5* |

| GSI540/200/4 | 26 | 14 | 23.2 | 15.9 | 12.8 | 11.8 | 3,5* |

| GSI600/200/4 | 32 | 18 | 31.3 | 22.7 | 16.2 | 15.7 | 5,9* |

| GSI660/200/4 | 44 | 24 | 50.3 | 39 | 21.1 | 19.6 | 7,3* |

| GSI720/200/4 | 44 | 24 | 50.3 | 39 | 20.7 | 23.5 | 10,0* |

| GSI780/200/4 | 50 | 26 | 55.8 | 46.1 | 21.8 | 25.5 | 11,4* |

| GSI840/200/4 | 56 | 30 | 63.8 | 53.2 | 24.5 | 29.4 | 14,1* |

| GSI900/200/4 | 62 | 32 | 67.8 | 56.7 | 25.4 | 31.4 | 15,4* |

| GSI960/200/4 | 68 | 34 | 71.8 | 60.3 | 26.2 | 33.3 | 16,8* |

| GSI1020/200/4 | 74 | 38 | 79.8 | 67.4 | 28.5 | 37.2 | 19,3* |

Tragfähigkeiten - Balken an Balken - Teilausnagelung

| Artikel | Charakter. Tragfähigkeit - Holz an Holz - Teilausnagelung | |||||

|---|---|---|---|---|---|---|

| Verbindungsmittel | Charakter. Tragfähigkeiten - Nadelholz C24 [kN] | |||||

| Hauptträger | Nebenträger | R1.k | R2.k | R3.k | R4.k | |

| Anzahl | Anzahl | CNA4,0x50 | CNA4,0x50 | CNA4,0x50 | CNA4,0x50 | |

| GSI380/100/4 | 8 | 4 | 9.2 | 3.3 | 3.3 | 3.9 |

| GSI440/100/4 | 12 | 6 | 13.3 | 6.7 | 4.8 | 5.9 |

| GSI500/100/4 | 14 | 8 | 16.8 | 8.8 | 6.1 | 6.9 |

| GSI540/100/4 | 16 | 8 | 19.9 | 11.1 | 5.9 | 7.8 |

| GSI600/100/4 | 20 | 10 | 23.9 | 16.3 | 7 | 9.8 |

| GSI660/100/4 | 22 | 12 | 27.9 | 19.2 | 8 | 10.8 |

| GSI720/100/4 | 26 | 14 | 31.9 | 24.8 | 8.8 | 12.7 |

| GSI780/100/4 | 28 | 14 | 31.9 | 24.8 | 8.3 | 13.7 |

| GSI840/100/4 | 32 | 16 | 35.9 | 28.4 | 8.9 | 15.7 |

| GSI900/100/4 | 34 | 18 | 39.9 | 31.9 | 9.5 | 16.7 |

| GSI960/100/4 | 38 | 20 | 43.9 | 35.5 | 10 | 18.6 |

| GSI1020/100/4 | 40 | 20 | 43.9 | 35.5 | 9.5 | 19.6 |

| GSI540/120/4 | 16 | 8 | 19 | 11.1 | 6.3 | 7.8 |

| GSI600/120/4 | 20 | 10 | 23.9 | 16.3 | 7.6 | 9.8 |

| GSI660/120/4 | 22 | 12 | 27.9 | 19.2 | 8.7 | 10.8 |

| GSI720/120/4 | 26 | 14 | 31.9 | 24.8 | 9.7 | 12.7 |

| GSI780/120/4 | 28 | 14 | 31.9 | 24.8 | 9.2 | 13.7 |

| GSI840/120/4 | 32 | 16 | 35.9 | 28.4 | 10 | 15.7 |

| GSI900/120/4 | 34 | 18 | 39.9 | 31.9 | 10.7 | 16.7 |

| GSI960/120/4 | 38 | 20 | 43.9 | 35.5 | 11.4 | 18.6 |

| GSI1020/120/4 | 40 | 20 | 43.9 | 35.5 | 10.8 | 19.6 |

| GSI500/140/4 | 12 | 6 | 14.3 | 6.7 | 5.2 | 5.9 |

| GSI540/140/4 | 14 | 8 | 16.8 | 8.8 | 6.9 | 6.9 |

| GSI600/140/4 | 18 | 10 | 21.8 | 13.6 | 8.3 | 8.8 |

| GSI660/140/4 | 20 | 10 | 23.9 | 16.3 | 8 | 9.8 |

| GSI720/140/4 | 24 | 12 | 27.9 | 21.3 | 9.3 | 11.8 |

| GSI780/140/4 | 26 | 14 | 31.9 | 24.8 | 10.4 | 12.7 |

| GSI840/140/4 | 30 | 16 | 35.9 | 28.4 | 11.4 | 14.7 |

| GSI900/140/4 | 32 | 16 | 35.9 | 28.4 | 10.9 | 15.7 |

| GSI960/140/4 | 34 | 18 | 39.9 | 31.9 | 11.8 | 16.7 |

| GSI1020/140/4 | 38 | 20 | 43.9 | 35.5 | 12.5 | 18.6 |

| GSI500/160/4 | 12 | 6 | 13.3 | 6.7 | 5.4 | 5.9 |

| GSI540/160/4 | 14 | 8 | 15.8 | 8.8 | 7.1 | 6.9 |

| GSI600/160/4 | 20 | 10 | 23.9 | 16.3 | 8.6 | 8.8 |

| GSI660/160/4 | 20 | 10 | 23.9 | 16.3 | 8.4 | 9.8 |

| GSI720/160/4 | 24 | 12 | 27.9 | 21.3 | 9.7 | 11.8 |

| GSI780/160/4 | 26 | 14 | 31.9 | 24.8 | 11 | 12.7 |

| GSI840/160/4 | 30 | 16 | 35.9 | 28.4 | 12.1 | 14.7 |

| GSI900/160/4 | 32 | 16 | 35.9 | 28.4 | 11.7 | 15.7 |

| GSI960/160/4 | 34 | 18 | 39.9 | 31.9 | 12.6 | 16.7 |

| GSI1020/160/4 | 38 | 20 | 43.9 | 35.5 | 13.5 | 18.6 |

| GSI500/180/4 | 12 | 6 | 12.2 | 6.7 | 5.5 | 5.9 |

| GSI540/180/4 | 14 | 8 | 14.7 | 8.8 | 7.2 | 6.9 |

| GSI600/180/4 | 20 | 10 | 23.9 | 16.3 | 8.8 | 8.8 |

| GSI660/180/4 | 20 | 10 | 23.9 | 16.3 | 8.6 | 9.8 |

| GSI720/180/4 | 24 | 12 | 27.9 | 21.3 | 10.1 | 11.8 |

| GSI780/180/4 | 26 | 14 | 31.9 | 24.8 | 11.4 | 12.7 |

| GSI840/180/4 | 30 | 16 | 35.9 | 28.4 | 12.6 | 14.7 |

| GSI900/180/4 | 32 | 16 | 35.9 | 28.4 | 12.2 | 15.7 |

| GSI960/180/4 | 34 | 18 | 39.9 | 31.9 | 13.3 | 16.7 |

| GSI1020/180/4 | 38 | 20 | 43.9 | 35.5 | 14.3 | 18.6 |

| GSI500/200/4 | 12 | 6 | 11.1 | 6.7 | 5.5 | 5.9 |

| GSI540/200/4 | 14 | 8 | 13.5 | 8.8 | 7.3 | 6.9 |

| GSI600/200/4 | 20 | 10 | 22.7 | 16.3 | 9 | 8.8 |

| GSI660/200/4 | 20 | 10 | 22.7 | 16.3 | 8.8 | 9.8 |

| GSI720/200/4 | 24 | 12 | 27.9 | 21.3 | 10.3 | 11.8 |

| GSI780/200/4 | 26 | 14 | 31.9 | 24.8 | 11.8 | 12.7 |

| GSI840/200/4 | 30 | 16 | 35.9 | 28.4 | 13.1 | 14.7 |

| GSI900/200/4 | 32 | 16 | 35.9 | 28.4 | 12.7 | 15.7 |

| GSI960/200/4 | 34 | 18 | 39.9 | 31.9 | 13.9 | 16.7 |

| GSI1020/200/4 | 38 | 20 | 43.9 | 35.5 | 15 | 18.6 |

Nagelbilder gem. ETA

Product characteristic capacities under fire conditions - Timber to timber with SSH

Installation

Installation

Befestigung

Die angegebenen Tragfähigkeiten des Verbinders sind gültig bei der Verwendung von CE gekennzeichneten Verbindungsmitteln nach ETA-04/0013.

Nebenträger:

CNA Kammnägel Ø 4.0x50 mm.

CNA Kammnägel Ø 4.0x35 mm bei einer Breite kleiner 64 mm.

CSA Schrauben Ø 5.0x40 mm.

CSA Schruaben Ø 5.0x35 mm ei einer Breite kleiner 60 mm.

R30 Ausführung: CNA Ø4.0 x 75 mm Kammnägel oder CSA 5,0 x 80-DE Schrauben

Hauptträger:

CNA Kammnägel Ø 4.0x50 mm.

CSA Schrauben Ø 5.0x40 mm.

R30 Ausführung: CNA Ø 4.0x75 mm Kammnögel oder CSA 5,0 x 80-DE Schrauben